Mosaic Sinkhole Site – Custom Rigging Solution for LIDAR Scanning

Location: Central Florida (Mosaic Facility)

Client: Mosaic Company / Monetrench Industrial

Industry: Environmental / Industrial

Project Type: Custom Rigging for LIDAR Survey Deployment

Project Overview:

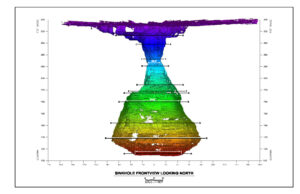

First Choice Marine Supply was contracted to design and supply a custom rigging setup to support the deployment of high-precision LIDAR scanning equipment over a massive sinkhole at a Mosaic phosphate facility. The goal was to ensure safe, stable, and accurate positioning of the equipment during environmental and structural assessments of the site.

FCMS leveraged their engineering experience, expertise of high-performance products, and state of the art rigging and fabrication capabilities to solve an extremely time sensitive problem that ultimately affected the supply and drinking water of the precious Florida’s Aquifer. Safety was of ultimate concern as the epicenter could not be approached for nearly ¼ mile. A deployable, innovative design was required to assess the catastrophic event in order to create a design for the remediation.

Scope of Work:

- Engineered a custom rigging solution capable of suspending sensitive LIDAR equipment over an unstable and restricted-access zone

- Supplied wire rope assemblies, beam clamps, synthetic slings, and load-rated hardware tailored for precision positioning

- Collaborated with environmental engineers to meet strict safety and operational requirements

- Provided on-site support and consultation to ensure accurate setup and functionality under variable field conditions

Outcome:

The successful design and execution of this custom rigging system enabled critical LIDAR data collection that informed Mosaic’s remediation and monitoring strategy. First Choice Marine Supply’s ability to problem-solve under complex industrial and environmental constraints showcased our depth of knowledge and versatility in the field of specialty rigging.